System: GCC

| Type | Fire protection closure as part of track-bound conveyor systems |

| Verification | ETA-16/0851 European Technical Assessment | VKF Technical Information No. 32235 |

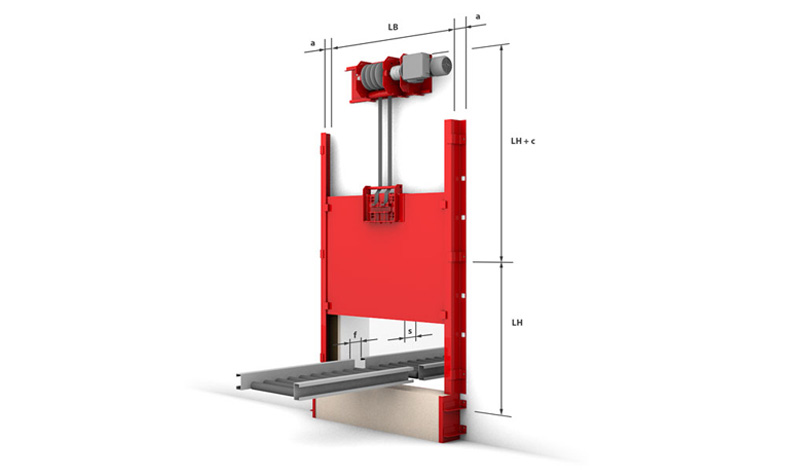

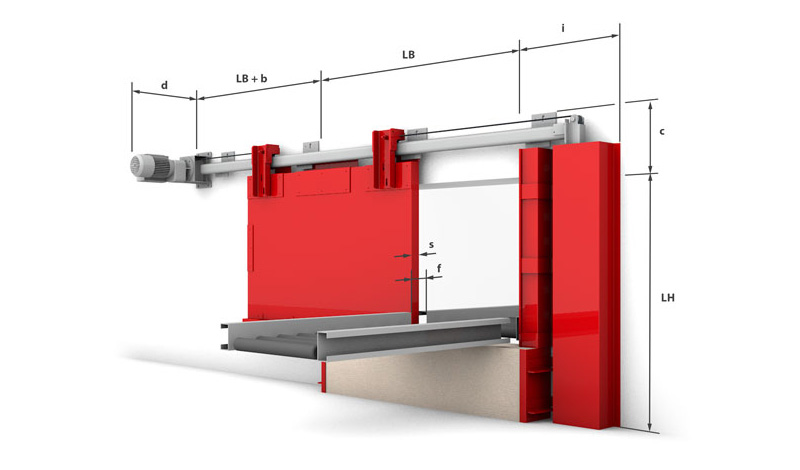

| Closing direction | From top to bottom | from left to right | from right to left |

| Fire resistance | EI1 90 | tested according to DIN EN 1366-7:2004 | classified according to EN 13501-2:2007 | Closing cycles | C4 | Number of closing cycles 100,000 | vertical closing direction C5 | Number of closing cycles 200,000 | horizontal closing direction |

| Reopening | motor |

| Conveyor system | Interrupted conveyor system | Inclined conveyor system | Continuous belt conveyor system | Continuous transfer carriage | Continuous suspension chain conveyor system | Continuous roller conveyor system | Continuous conveyor system |

| Visible surfaces | Attachment parts: galvanised | coated in RAL colour | stainless steel 1.4301 (V2A) Fest panel and damper blade: untreated fire protection boards | painted with dispersion paint in a similar RAL colour | galvanised sheet metal cladding | sheet metal cladding stainless steel 1.4301 (V2A) | sheet metal cladding coated in RAL colour |

Size dimensions and system design

Due to the combination of classifications or the ratio of clear system width to clear system height, the stated maximum dimensions may be reduced and the dimensions of the enclosure and guide rails may vary. The specifications on the quotation apply.

| Component (supporting structure) in which the closure may be installed | achievable Fire resistance class | |||

| largest width LB | greatest height LH | largest surface | ||

| Solid high-density wall, masonry or solid concrete with a total density of ≥ 800 kg/m3 and a thickness ≥ 150 mm | EI1 90 EI2 90 | 3.600 mm | 4.200 mm | 10,0 m2 |

| Solid low-density wall, aerated concrete with total density of ≥ 450 kg/m3 and thickness ≥ 150 mm | EI1 90 EI2 90 | 3.600 mm | 4.200 mm | 10,0 m2 |

The installation situation must comply with the building code requirements of the country of installation. The fire resistance of a ceiling or wall support structure and the adjacent components must at least correspond to that of the fire protection closure. Proof of the stability and serviceability of the adjacent walls and components must be provided under general ambient conditions and in the event of fire. See also notes on the standard supporting structure in EN1366-7:2004 or EN1363-1:2020. The fire protection system must not be subjected to any additional loads other than its own weight, even in the event of fire.