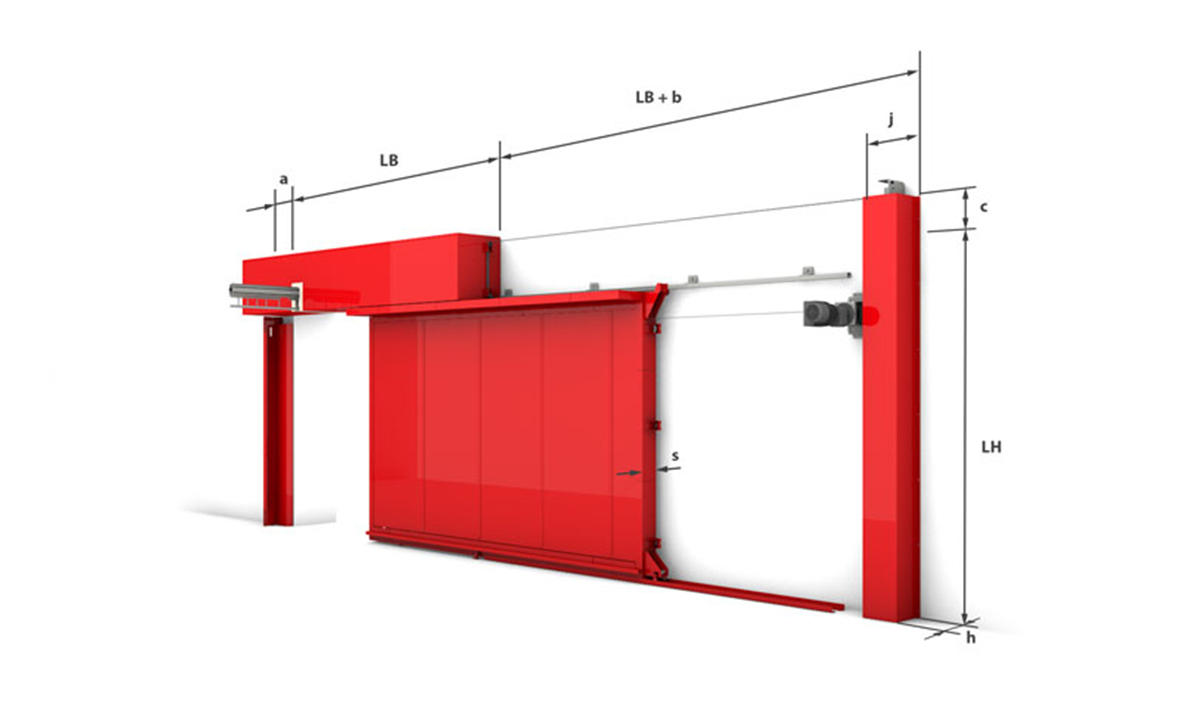

Product description

Combination of gate and collar for complex conveyor systems ECClos®-K is the robust and safe gate solution for circular conveyors and Power&Free Systems. The system uses intumescent collars to safely shield continuous circular conveyors and is also suitable for the passage of several conveyor lines. The damper in sandwich design features is completely enclosed by a sheet metal casing and thus very sturdy. Especially convenient for transport and easy installation: ECClos®-K is delivered in compact segments that are easy to assemble.