STÖBICH awards Kaiser Friedrich Research Prize in Hanover

Every two years, STÖBICH awards prizes to innovative research projects in the field of optical technologies. This year, the Kaiser Friedrich Research Prize went to the OPTIMUS team of Leibniz Universität Hannover for excellent environmental and climate protection.

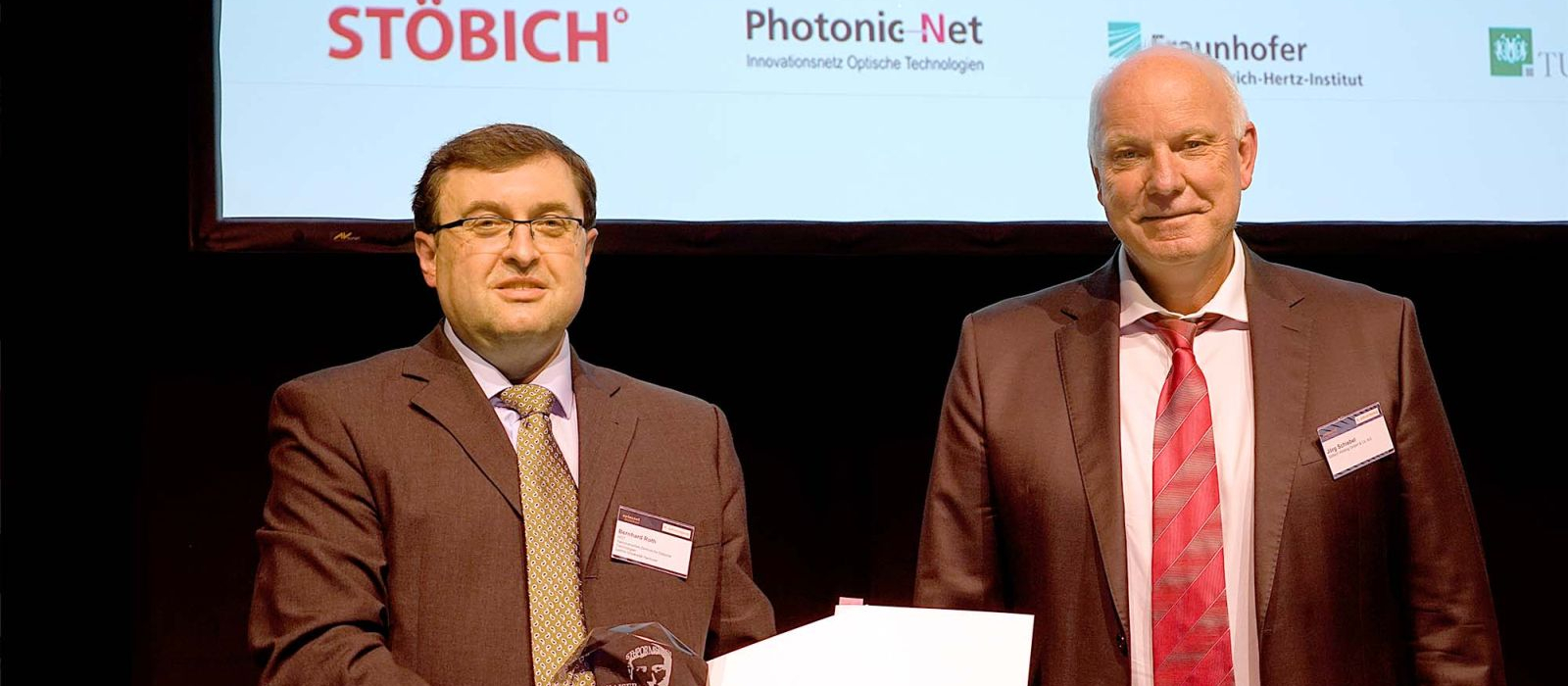

Prof. Bernhard Roth, a member of the PhoenixD cluster of excellence at Leibniz Universität Hannover, accepted the research prize of 15,000 euros with obvious pride, also on behalf of his colleague Dr Ann-Kathrin Kniggendorf, who was unable to attend the event. The award ceremony, which is otherwise traditionally held in the Kaiserpfalz Goslar, had already been postponed twice and now took place as part of the 4th OptecNet Annual Conference at Expowal Hannover. Jörg Schiebel, CEO of the STÖBICH Group, presented the coveted trophy on 24.11.2021 in a festive atmosphere: The company founder and innovation driver Dr.-Ing. Jochen Stöbich, who passed away in the spring, had initiated the Kaiser Friedrich Research Prize at the time.

The fact that the award ceremony had to be delayed by a year due to the pandemic does not detract from the outstanding achievements of the prize-winning scientists. The team led by Dr. Ann-Kathrin Kniggendorf and Prof. Bernhard Roth from the Hanover Centre for Optical Technologies (HOT) has developed a method that detects microplastics in water using optical technologies. The plastic particles, some of which are microscopic, enter the environment, our drinking water and our food in various ways and thus ultimately end up in our bodies. The detection and elimination of these unwanted particles is therefore also a high priority for society - and this is where the OPTIMUS project, funded by the Federal Ministry of Education and Research, comes in.

Where previously complicated samples were necessary, the mobile measuring system uses laser light to determine within milliseconds how heavily the water is polluted with which type of microplastic. As a result, not only can possible damage to health be averted more efficiently; the cause of the contamination can also be determined more precisely and, at best, remedied promptly. This makes OPTIMUS "a real innovation in the field, as currently such investigations can only be carried out with expensive analytical procedures in the laboratory," says Roth. "The system works with purely optical measurement methods," explains Dr Ann-Kathrin Kniggendorf, group leader at HOT in the area of environmental analysis. "

An ingenious idea that would certainly have appealed to our company founder, Dr Jochen Stöbich. He was convinced that light as a tool has a special significance as a cross-sectional technology and an important key for innovations in numerous branches of industry.

We congratulate the research group on this important invention, which is at the same time a sustainable contribution to the protection of nature and the quality of life of us all. More information is available here: https://www.phoenixd.uni-hannover.de/.