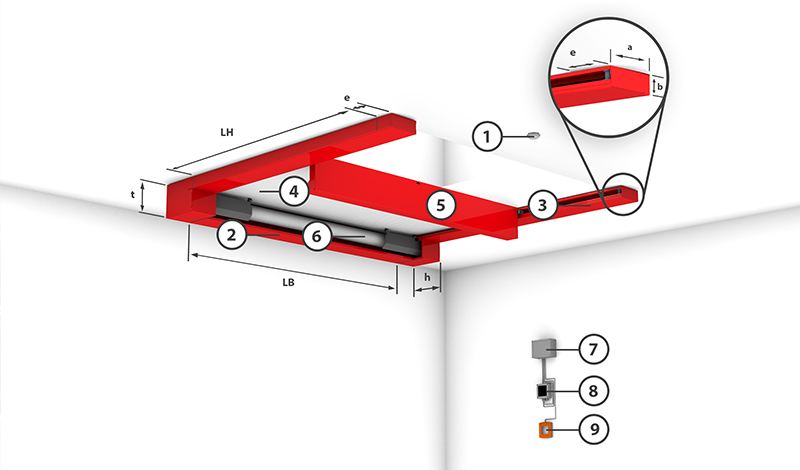

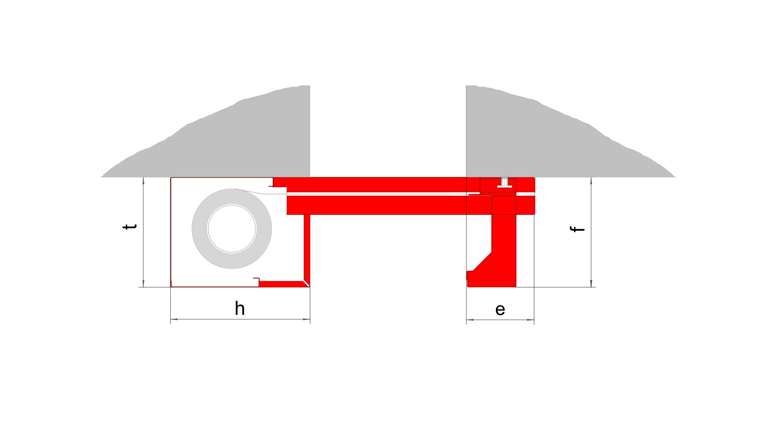

| Type | Radiation-reducing, room-enclosing fire protection closure of textile design |

| Verification | CE marking according to hEN 16034 : 2014 in conjunction with hEN 13241 : 2003+A2 : 2016 |

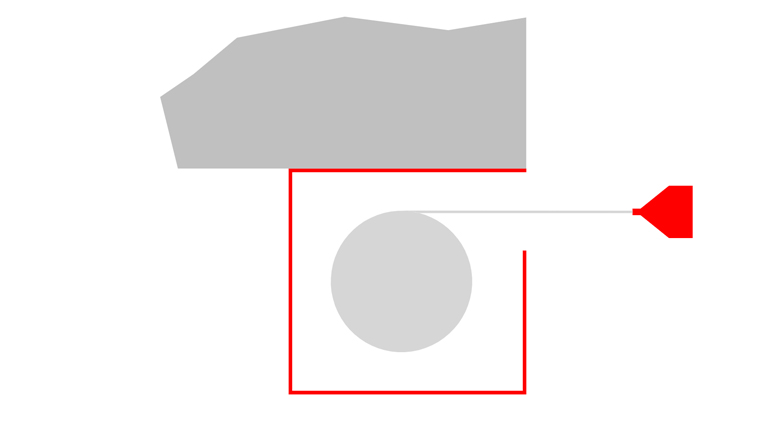

| Closing direction | horizontal |

| Fire resistance | E 120 | EW 90 | tested according to EN 1634-1 : 2014-03 | classified according to EN 13501-2 : 2016-12 |

| Closing cycles | C, C1 | tested according to EN 12605 : 2000-08 | classified according to EN 13501-2 : 2016-12 |

| Durability | C: for 2-part systems up to size 9400 x 18800 mm for E 120 and EW 60 or 6800 x 4270 mm for EW 90

C1: for 1-part systems up to size 5000 x 5000 mm for EW 60 or 6000 x 6500 mm for E 120 and EW 30 |

| Environmental conditions | In the event of a fire, the falling of ceiling parts in the area of the the area of the soffit by suitable on-site measures on the part of the customer. Not taken into account are special environmental conditions (for example Humidity >80%, ambient | Special environmental conditions are not taken into account (e.g. humidity > 80 %, ambient temperature < 5 °C and > 45 °C, wind loads etc.) |