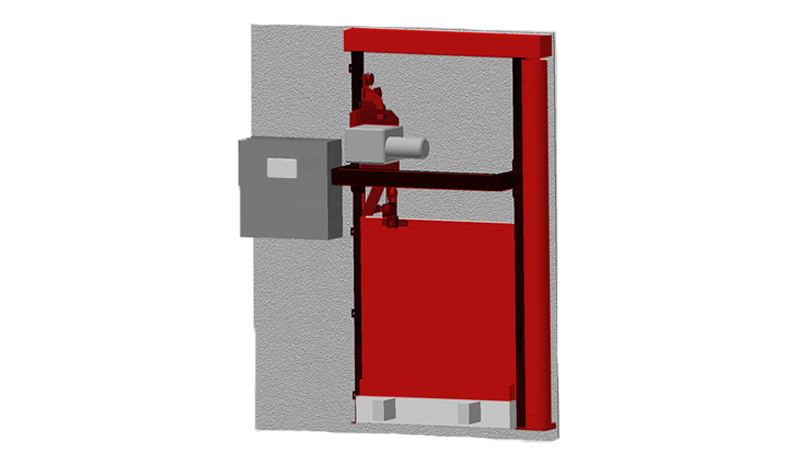

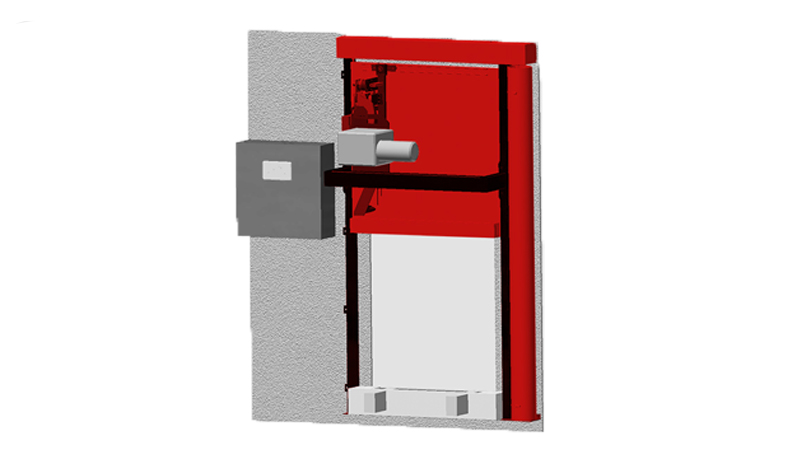

SYSTÈME : BR 100 (ÉGALEMENT AVEC FONCTION RAPIDE)

| Type de construction | Fermeture coupe-feu au cours des installations de transport liées à la voie |

| Preuve de conformité | ETA-16/0851 Evaluation technique européenne (BR 100 EU) | Z-6.6-2089 Approbation générale de la construction/approbation générale du type de construction (BR 110 D) | VKF Renseignements techniques no 32801 (BR 100 E) |

| Direction de la fermeture | de haut en bas | de bas en haut | de gauche à droite | de droite à gauche | horizontale à deux vantaux fermant vers le centre |

| Résistance au feu | Jusqu'à EI2 90 | testé selon EN 1366-7:2004 | classé selon EN 13501-2:2007 |

| Cycles de fermeture | Jusqu'à C5 | 200.000 cycles de fermeture | classé selon DIN EN 13501-2:2007 |

| Réouverture | motorisé ou manuel |

| Systèmes de convoyage | Technique de convoyage à bande | Technique de convoyage à chaîne porteuse | Technique de convoyage à rouleaux | monorail électrique suspendu | Power & Free |

| Surfaces visibles | Zingué, RAL |

Dimensions et structure du système

Les spécifications des différentes versions du produit en termes de classification, de taille du système et de qualité de paroi requise pour la série BR 100 sont indiquées dans les fiches techniques correspondantes.

La situation de montage doit être conforme aux exigences légales de construction du pays de montage. La résistance au feu d'une construction porteuse de plafond ou de mur et des éléments de construction adjacents doit correspondre au moins à celle de la fermeture coupe-feu et/ou pare-fumée/rideau coupe-feu et/ou pare-fumée. La preuve de la stabilité et de l'aptitude au service des parois et éléments de construction adjacents doit être apportée dans les conditions ambiantes générales et en cas d'incendie. Voir également les indications relatives à la structure porteuse normalisée dans la norme EN1366-7:2004 ou EN1363-1:2020. Le système de protection incendie ne doit pas non plus être soumis à une charge supplémentaire en cas d'incendie, hormis son propre poids.