Description du produit

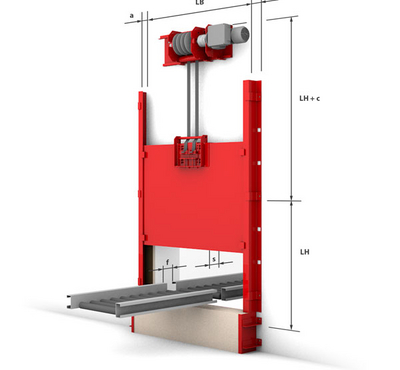

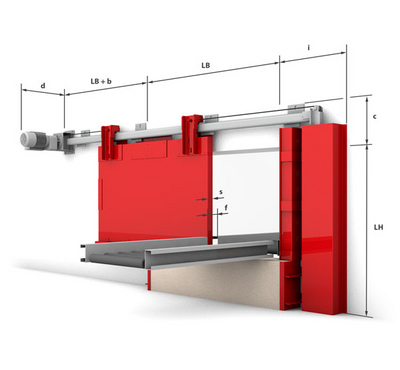

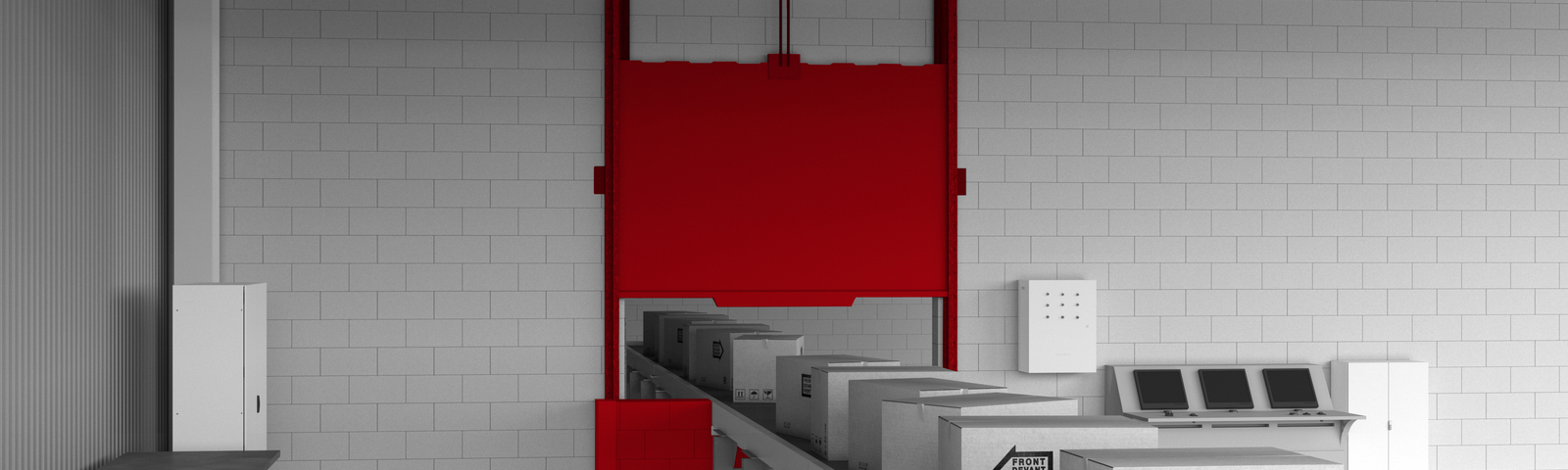

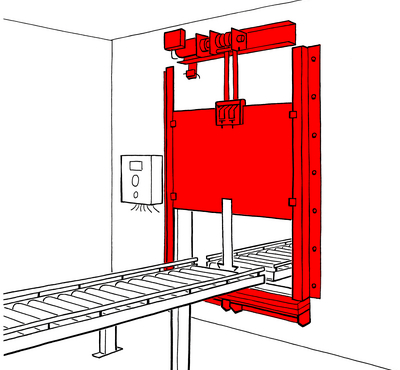

Global Conveyor Closure (GCC) est une fermeture de convoyeur compacte en construction par éléments destinée à des convoyeurs continus et interrompus. Ce système ne nécessite qu'un faible recouvrement sur le mur autour de l’ouverture. En raison de l’épaisseur minimale de la pale du coulisseau et dans le cas de systèmes de transport interrompus, seule une très légère interruption du convoyeur (point de séparation) est nécessaire. Les possibilités de conception de la surface de la pale du coulisseau vont d’une version de base économique constituée de panneaux non traités en passant par un laquage avec des peintures de dispersion jusqu’à un habillage haut de gamme de la surface du coulisseau avec une tôle en acier galvanisée (en option, à revêtement par poudre ou en acier inoxydable).

Type de construction | Fermeture coupe-feu dans le cadre des convoyeurs sur rails |

Justificatif d'aptitude à l'utilisation | European Technical Assessment - ETA |

Sens de fermeture | Du haut vers le bas • de gauche à droite • De droite à gauche |

Résistance au feu | EI1 30 • EI1 60 • EI1 90 • Contrôlé selon DIN EN 1366 |

Cycles de fermeture | C5 Nombre de cycles de fermeture 200 000 |

Réouverture | Motorisé (standard) |

Système de convoyage | Convoyeur discontinu • Voie en pente • Convoyeur à courroie continu • Chariot mobile • Convoyeur à rouleaux continu • Convoyeur à chaîne porteuse continu |

Téléchargements

Qualité requise du mur | |

|---|---|

Maçonnerie | ép ≥ 150 mm |

Béton | ép ≥ 150 mm |

Béton cellulaire | ép ≥ 150 mm |

Construction en acier à planches | selon DIN 4102-4 |

Domaine d’autorisation (max 10,00 m²) | |

|---|---|

LI | 3 600 mm |

HI | 4 200 mm |

Faisabilité technique | |

|---|---|

LI | 3 600 mm |

HI | 4 200 mm |