Reliable protection against flames and smoke

STÖBICH - world market leader in structural fire protection

STÖBICH Brandschutz GmbH has been the technology and global market leader in preventive structural fire protection for 45 years and produces standard constructions and customised solutions for outstanding architectural and industrial projects. Production takes place exclusively in Germany. With a high export share and numerous foreign subsidiaries as well as selected sales partners, the company is represented in more than 50 countries around the globe.

Over 45 Years of STÖBICH

The Goslar-based family business has its origins in 1978, when a major fire in a Bahlsen factory caused millions in damage because the fire was spread to several parts of the factory through the necessary wall openings via conveyor systems. It was precisely for these openings in walls and ceilings that Dr Jochen Stöbich designed the first ➥ Fire protection closures for continuous conveyor technology - the basis for rapid development and the impetus for founding STÖBICH Brandschutz 1980.

Courage and enthusiasm for technology - Made in Germany

Over 150 patent applications and 12 successfully established world firsts on the market

STÖBICH has developed into a fire protection specialist thanks to a wide range of fire tests and numerous successfully completed construction projects. The company has been setting standards for 45 years and is a world leader in terms of innovative strength and key technologies. The company's many years of experience and expertise have resulted in ground-breaking innovations time and time again. With every new development, the demand for improved design system properties and higher product protection targets grows.

STÖBICH has been listed in the lexicon of German world market leaders since 2010, was recognised as a top innovator in 2015, 2018, 2021 and 2024 and was also named Germany's innovation leader in 2020.

Pioneer in structural fire protection

The company's constant focus on innovation and the expertise it has built up over decades have resulted in ➥ fire protection solutions for almost every conceivable application. Particularly in the processing of fire and smoke-proof textiles, STÖBICH Fire Protection, as an innovation leader and using state-of-the-art materials, develops pioneering products that meet both architectural and technical requirements.

Thanks to the immense number ➥ of successfully completed construction projects and a wide range of fire tests, STÖBICH has developed into a fire protection specialist. The expertise gained during this time is reflected in the company's wide range of products and comprehensive range of services.

Our engineers' many years of experience and expertise are constantly producing pioneering innovations. With each new development, the demand for improved design system properties and higher protection targets for our products grows. The continuous improvement of ➥ STÖBICH solutions, new ideas and their cost-effective implementation have ensured the company's leading role in the field of fire protection since its foundation in 1980.

Production location Germany

From standard designs to customised solutions

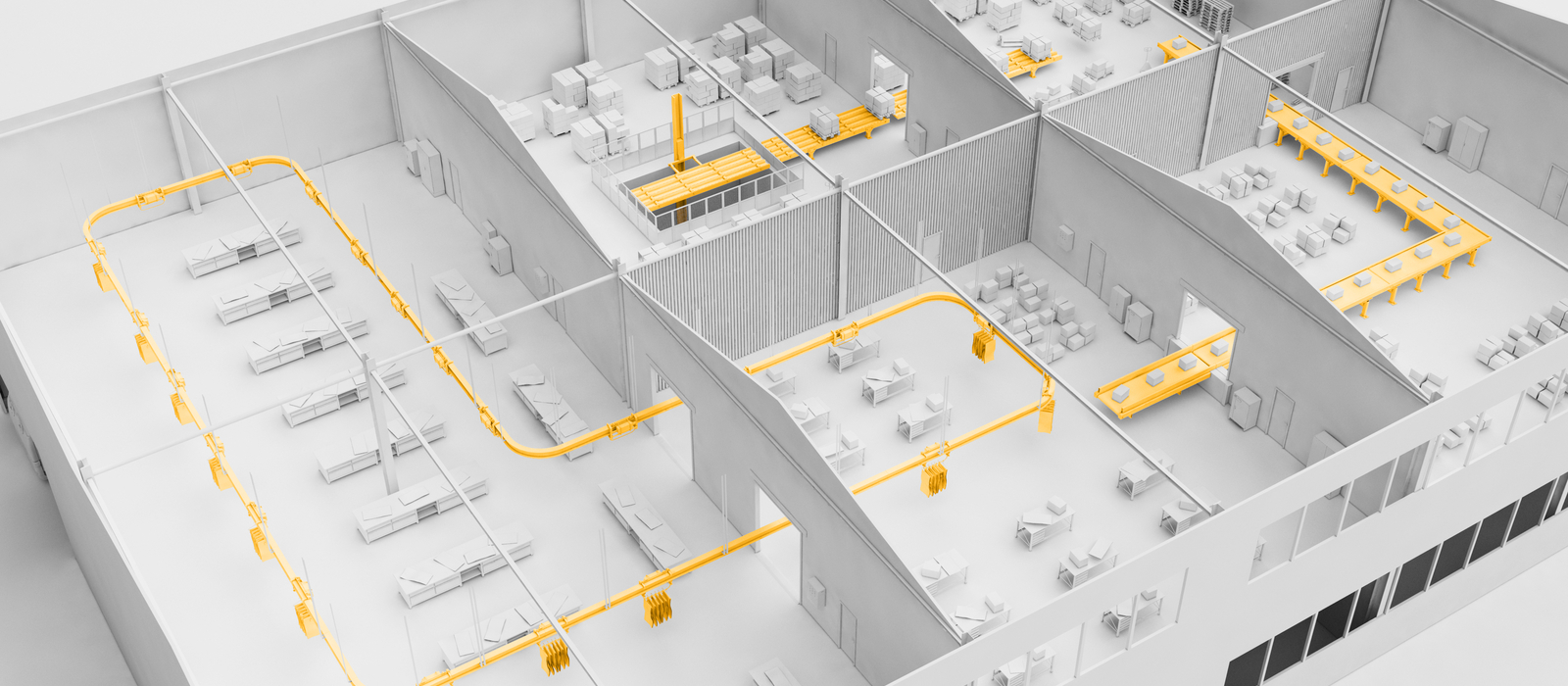

STÖBICH develops and produces exclusively in Germany. Whether ➥ Conveyor system closure, ➥ Fire protection curtain or ➥ Smoke protection curtains - all systems are manufactured at the Goslar site. Precision, permanent monitoring and long-term supplier loyalty are the quality standards that apply.

Whether control system construction, sheet metal processing or fabric development, the expertise and manufacturing processes are located within the STÖBICH group of companies.

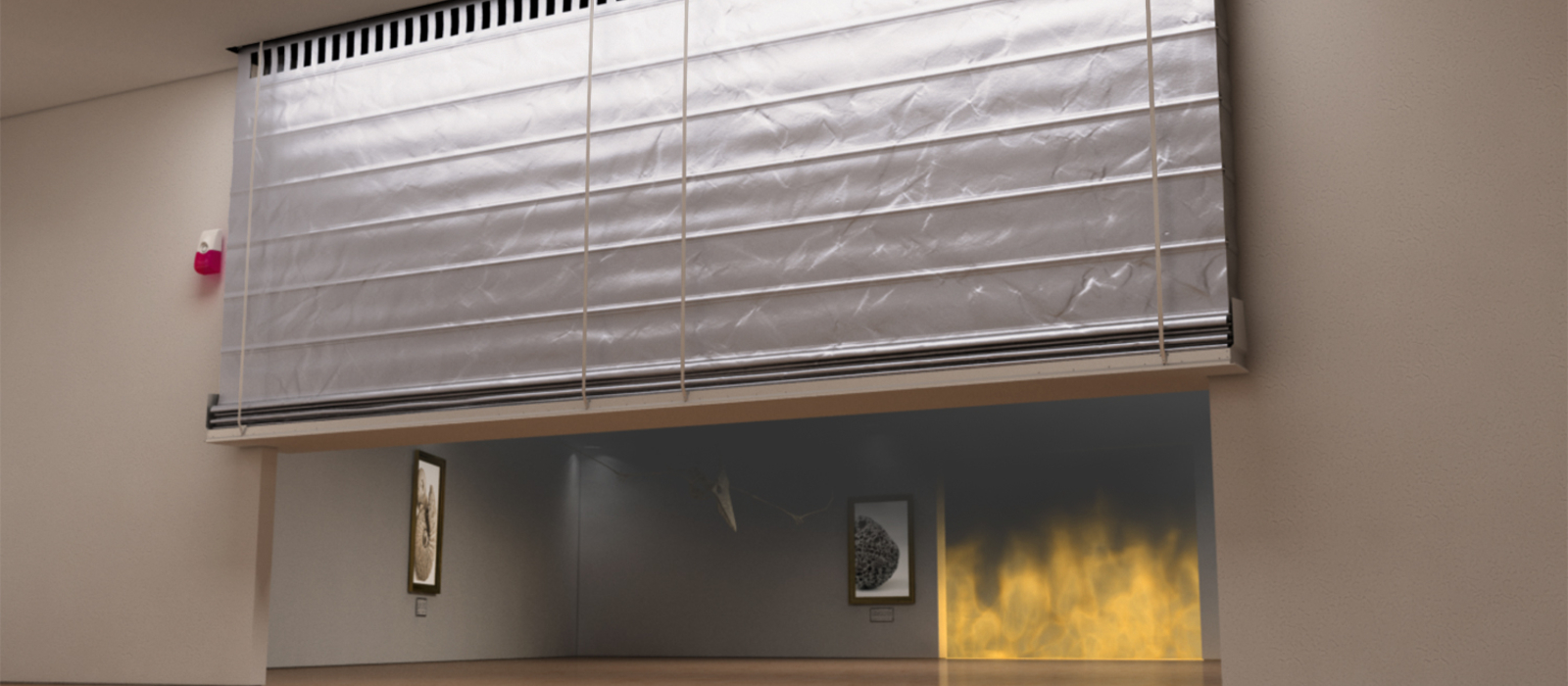

Textile fire protection

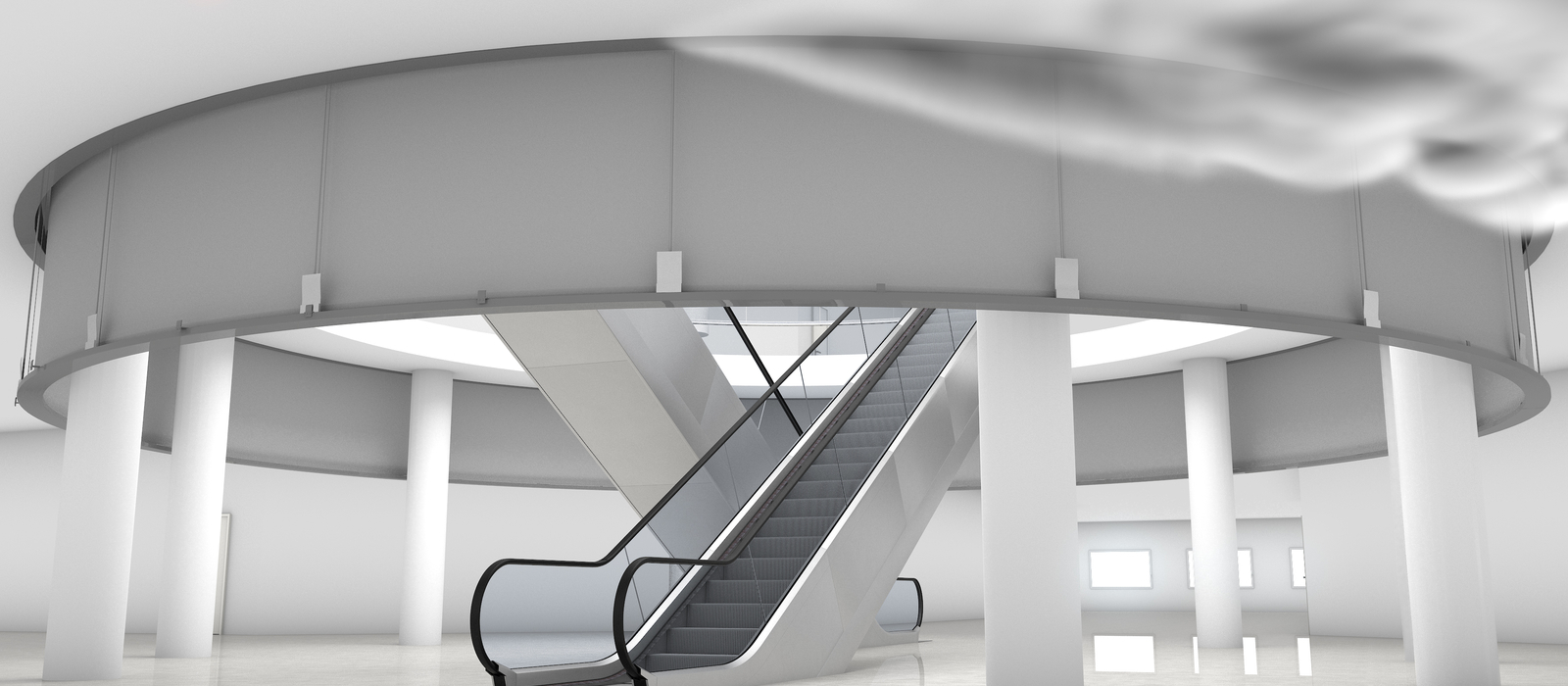

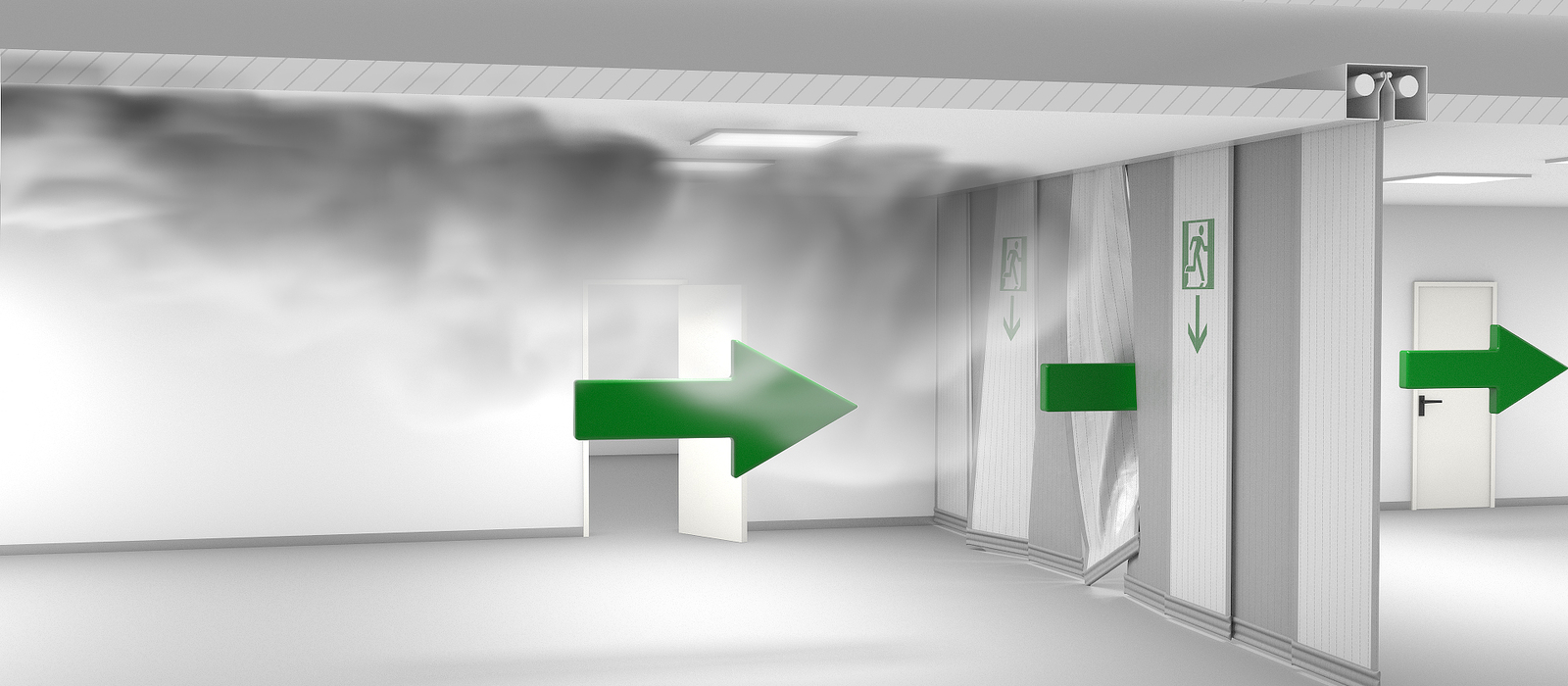

Fire protection should work, but not stand out! Because outstanding architecture is characterised by harmony of form and function. Textile fire protection combines aesthetics and functionality and enables open room concepts despite strict fire protection regulations. If the structural separation into fire compartments or the creation of large smoke barriers is required, many fire protection solutions interfere with the room concept, sometimes considerably.

Fire protection curtains, smoke barriers and textile smoke protection closures from STÖBICH are available in a very wide range of designs and offer almost invisible integration into sophisticated and open architecture. Variable installation variants, even round or corner penetration seals and the closure of extremely large wall and ceiling openings make fire and smoke protection curtains from STÖBICH true all-rounders for a wide range of protection objectives.

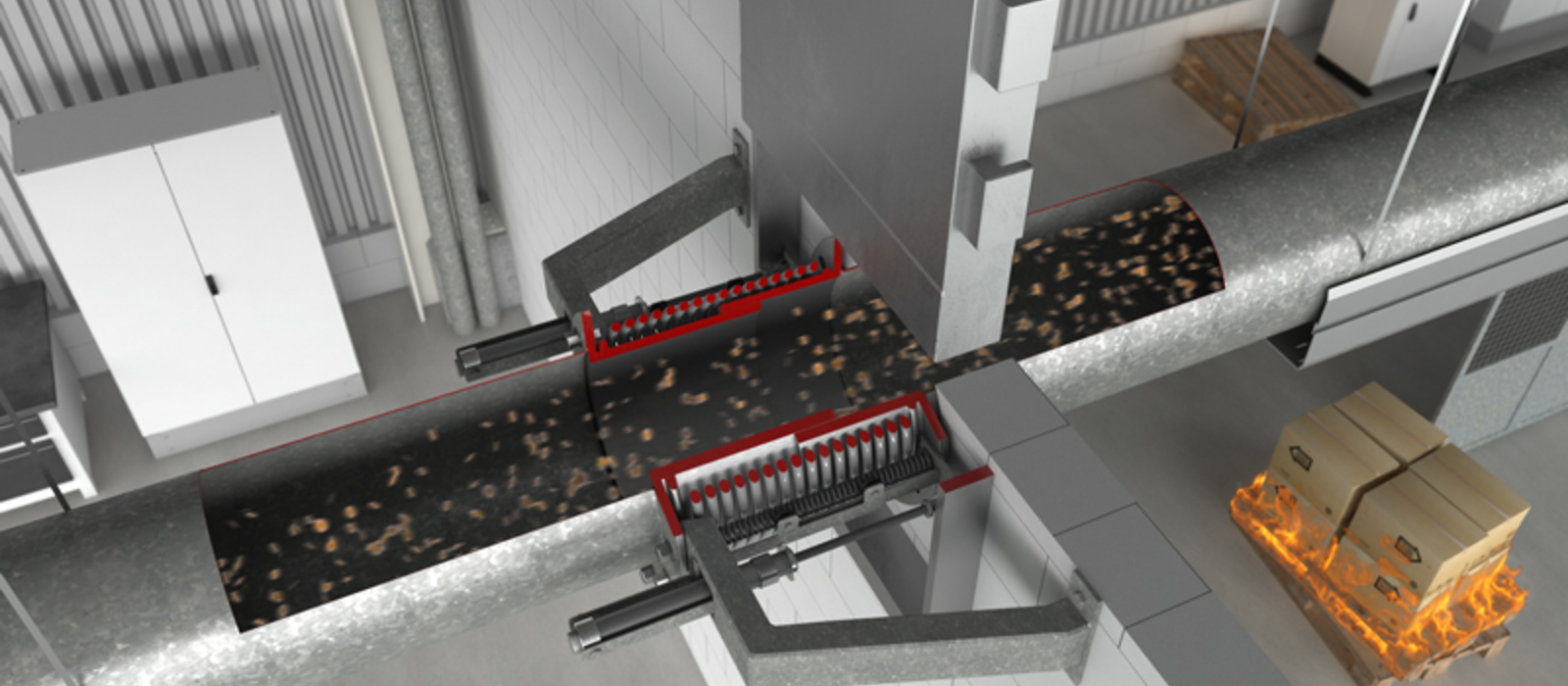

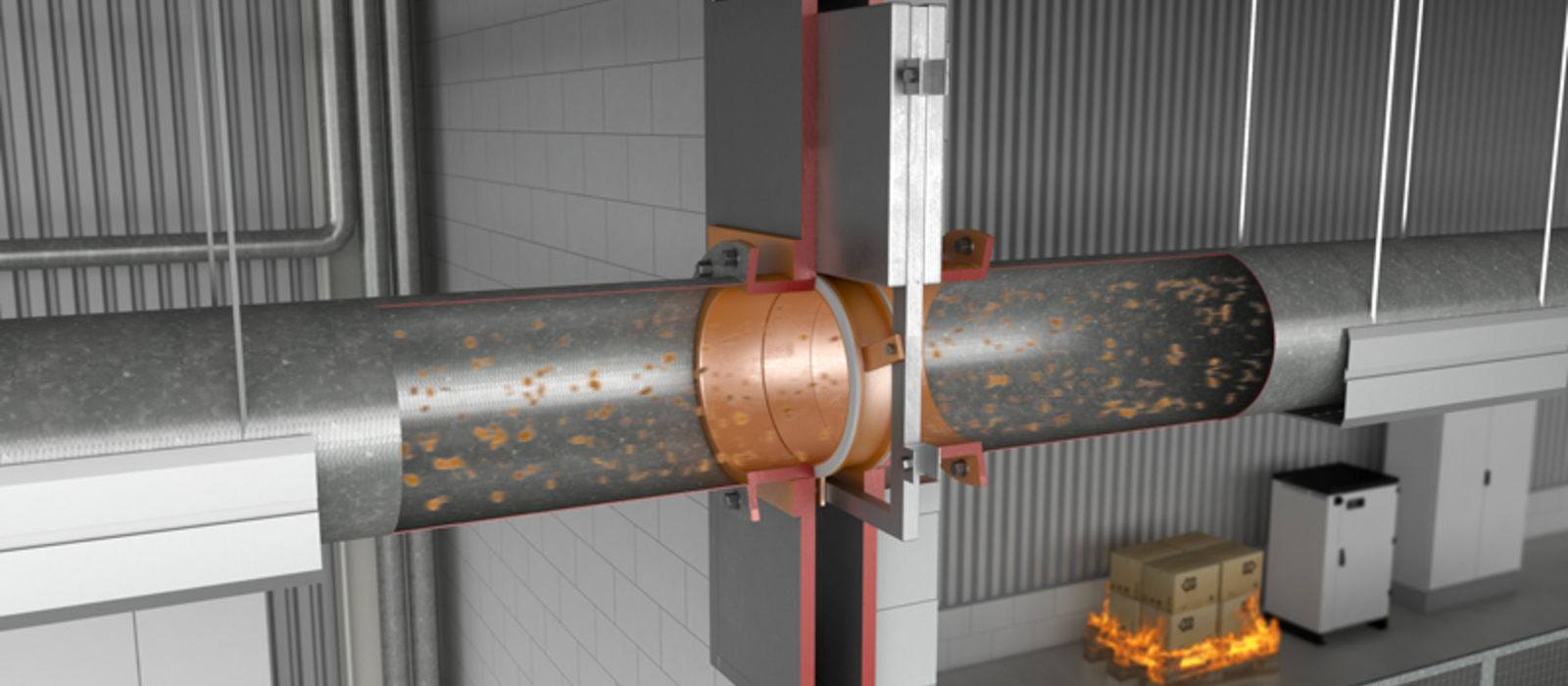

Fire protection for conveyor systems

The development has a history. In 1978, a major fire at the Bahlsen plant in Berlin caused millions in property damage. At that time, the conveyor belts affected had transported the fire to several areas of the hall complex. The avoidable damage in this case totalled around DM 6 million. The reason was that at that time there were neither functioning nor tested designs on the market for sealing off continuous conveyor systems.

Jochen Stöbich designed the first fire protection closures for this application. Whether as a sliding design, flap construction, swing door or sectional door: today, there is a suitable compartmentalisation solution for almost every installation situation and conveyor system variant. Every FAA must contribute to a trouble-free conveying process and must not hinder it. Conveyor system manufacturers therefore require safe interaction between the conveyor system and the FAA as well as a reliable closing process.

The performance of modern fire protection textiles

When looking at a fabric that is only 1 mm thick, it may be hard to believe that it can achieve a fire resistance that is in no way inferior to that of solid closures such as doors or gates. However, modern textiles can easily withstand temperatures of more than 1,000°C and have been proven to remain intact for several hours. What's more, curtain systems of this kind can even reduce radiation transmission by around 90 % with the right fabric structure. However, the production of these high-tech fabrics requires a great deal of development work as well as complex weaving, coating and laminating techniques.

Excellent fire protection

In over 45 years of inventiveness, innovative spirit and experience in preventive structural fire protection, STÖBICH has not only grown into a successful company. STÖBICH has become a brand that stands for customised fire protection solutions, for expertise in the development, manufacture and installation of conveyor system closures and fire or smoke protection curtains. A brand that creates long-term trust with customers through solution-orientated advice. A brand that continues to inspire architects and planners with modern concepts and ideas. Numerous prizes and awards testify to the success story of the Goslar-based family business.

The Stöbich Group

More than the sum of its companies

The STÖBICH Group comprises upstream and downstream areas of the actual value chain. The STÖBICH Group includes companies in the fields of control electronics, fabric development, insulation technology, optical measurement technology, pollutant and fire damage restoration, software development, new technologies and service and maintenance.