| Type | Fire protection closure as part of track-bound conveyor systems |

| Proof of usability | European Technical Assessment - ETA (EU) | Certificate of Constancy of Performance (UK) | VKF Technical Information No. 32211 |

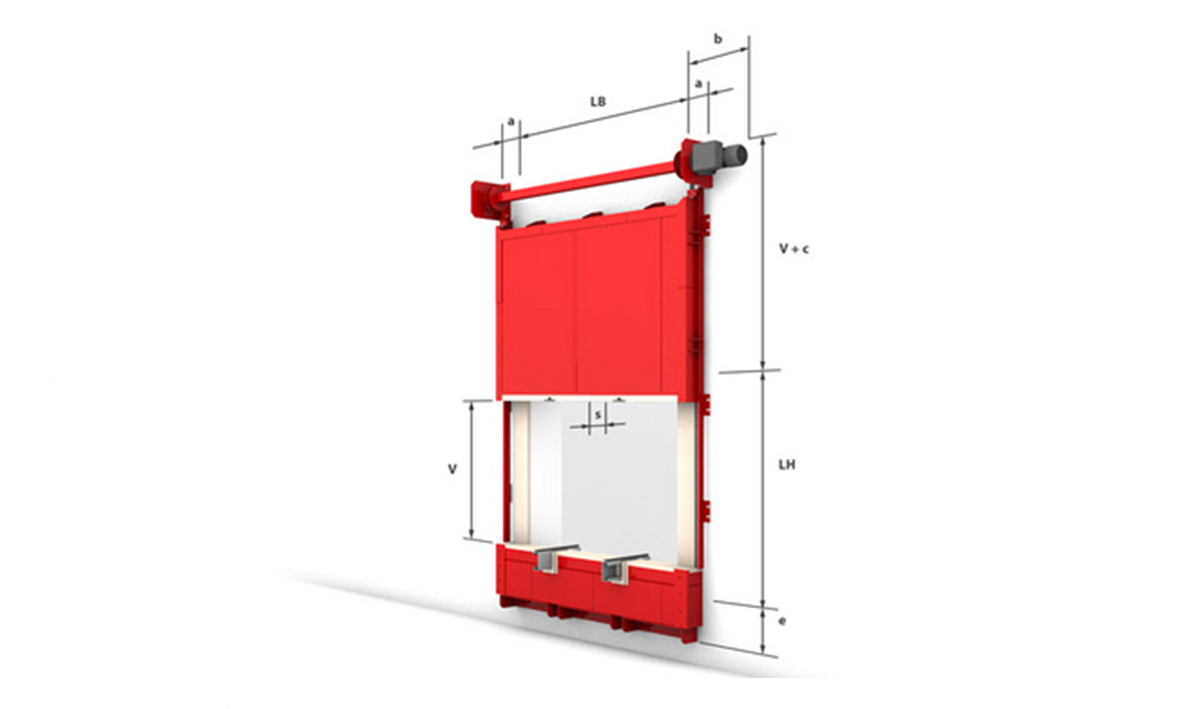

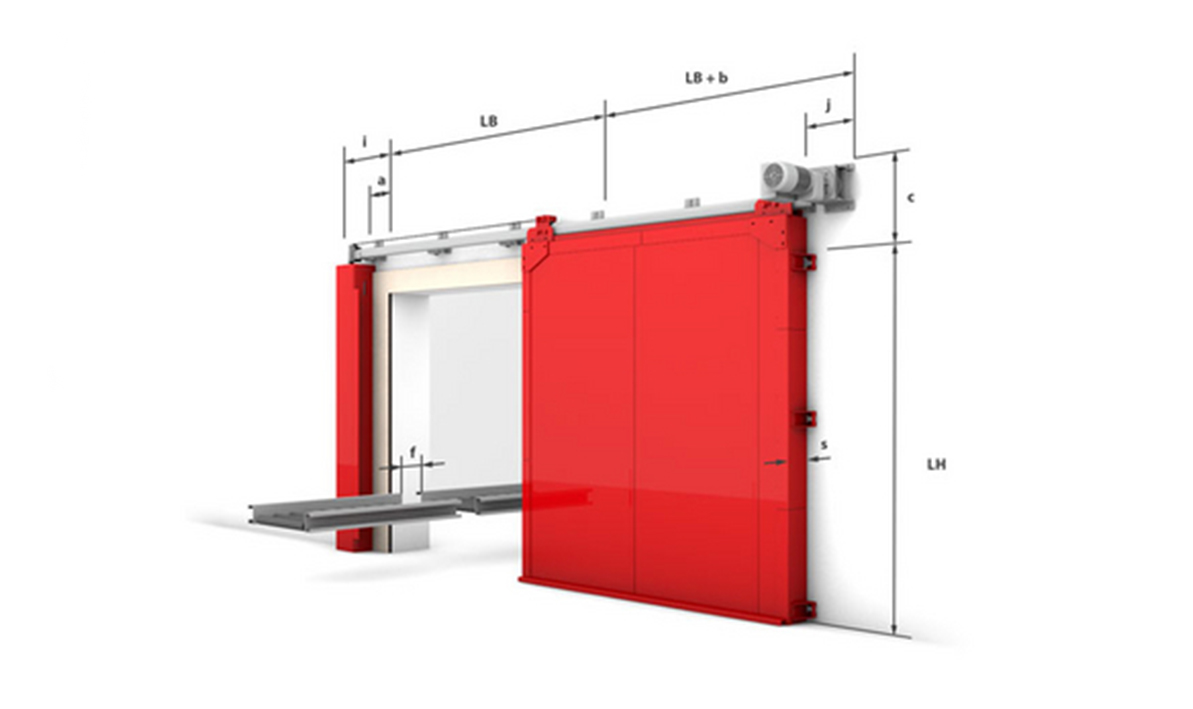

| Closing direction | from left to right | from right to left | From top to bottom |

| Fire resistance | EI₁ 120 | (2 hours integrity and 2 hours minutes insulation) in accordance with European test standard according to EN 1366-7 |

Closing cycles | C5 number of closing cycles 200,000 | classified according to DIN EN 13501-2 | | Re-opening | electromotive (standard) | manual |

| Conveyor system | Skid Conveyor | Inclined Conveyor | Interrupted Conveyor | Continuous Belt Conveyor | Continuous Traverser | Continuous Chain Conveyor | Continuous Roller Conveyor | Continuous Conveyor Technology |