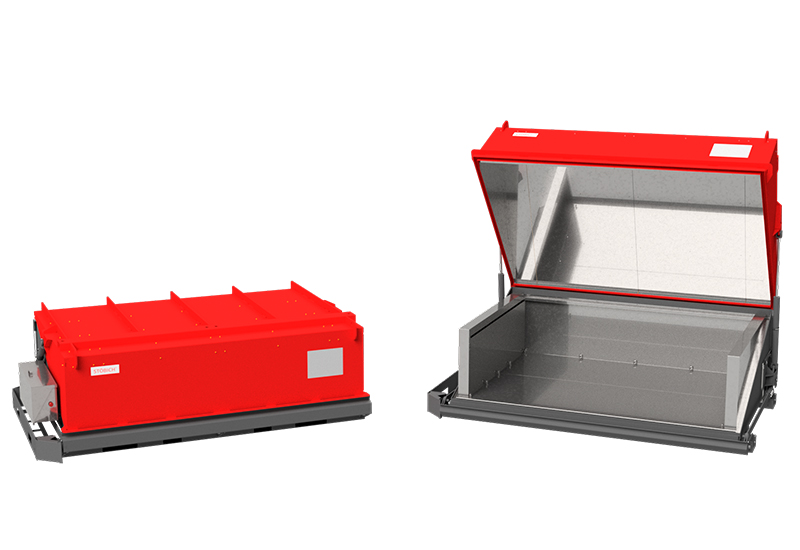

Product description

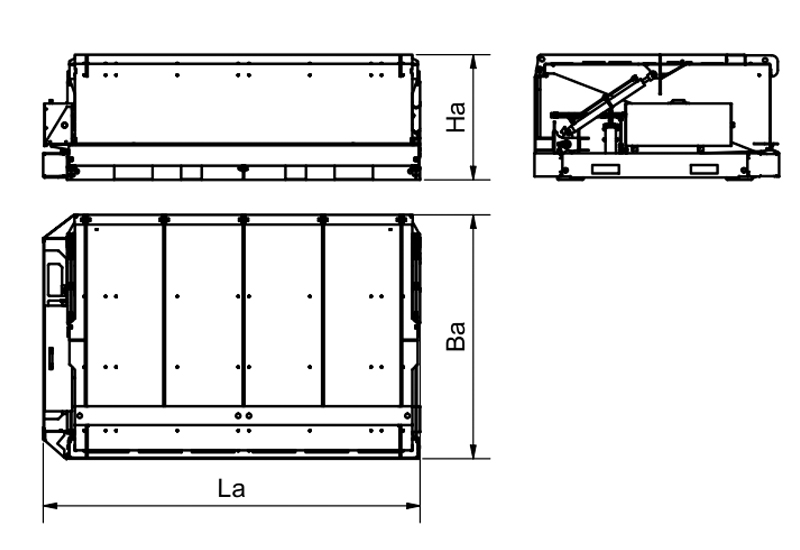

The StrainBox XL makes it possible to transport critical and defective lithium-ion batteries in an ADR-compliant manner and to store them safely. The size and construction have been specially designed for the storage and transport of batteries and modules, such as those installed in battery electric vehicles.

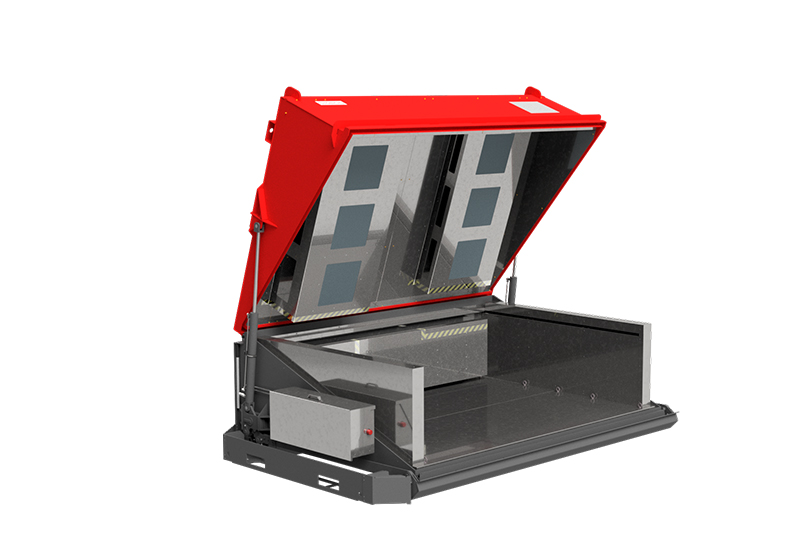

All packaging in the StrainBox series has an integrated filter system that filters out toxic gases to a large extent. Dust and particles that are harmful to health are retained and the escape of solids, liquids and flames is prevented.

Due to the integrated thermal management, there is no critical temperature increase of the outer walls. If the batteries inside should accident, contamination around the packaging is prevented.

To protect people and property, the StrainBox XL also has the typical safety features that only products from Stöbich Brandschutz GmbH offer. These include the filter system, the mechanically resistant design and the integrated thermal management.