More sustainable fire protection: today, tomorrow and the day after tomorrow

The STÖBICH sustainability strategy

For us, sustainability is more than just saving electricity through LED lighting (we have), electric cars and JobRad (we ride) or product packaging made from 80% recycled materials (which has also long been standard for us).

Our concept of sustainability takes place on your premises:

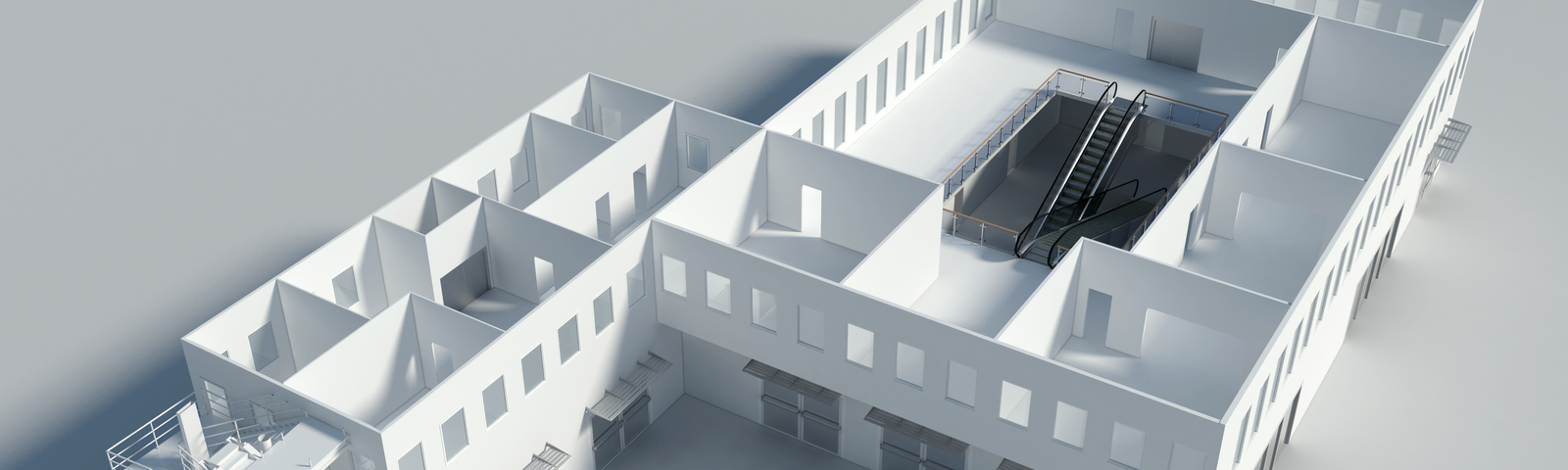

We already offer our customers options for reducing the use of solid walls with textile fire protection, designing rooms to be open and transparent and making buildings more flexible to use. We are breaking new ground with clever concepts and working on the development of more climate-friendly materials for their future use in our products.

SHAPES

OR

FLEXIBLE

SOLUTIONS?

We live corporate social responsibility

As an innovation driver and global market leader, we are aware of our responsibility towards people and the environment. Together with other global players, we pursue the 17 UN Sustainable Development Goals of Agenda 2030, to which our Code of Conduct also refers. With regard to our corporate responsibility, we have voluntarily committed to Corporate Social Responsibility (CSR), which comprises three areas of responsibility:

Janine Stöbich-Uffel, Shareholder