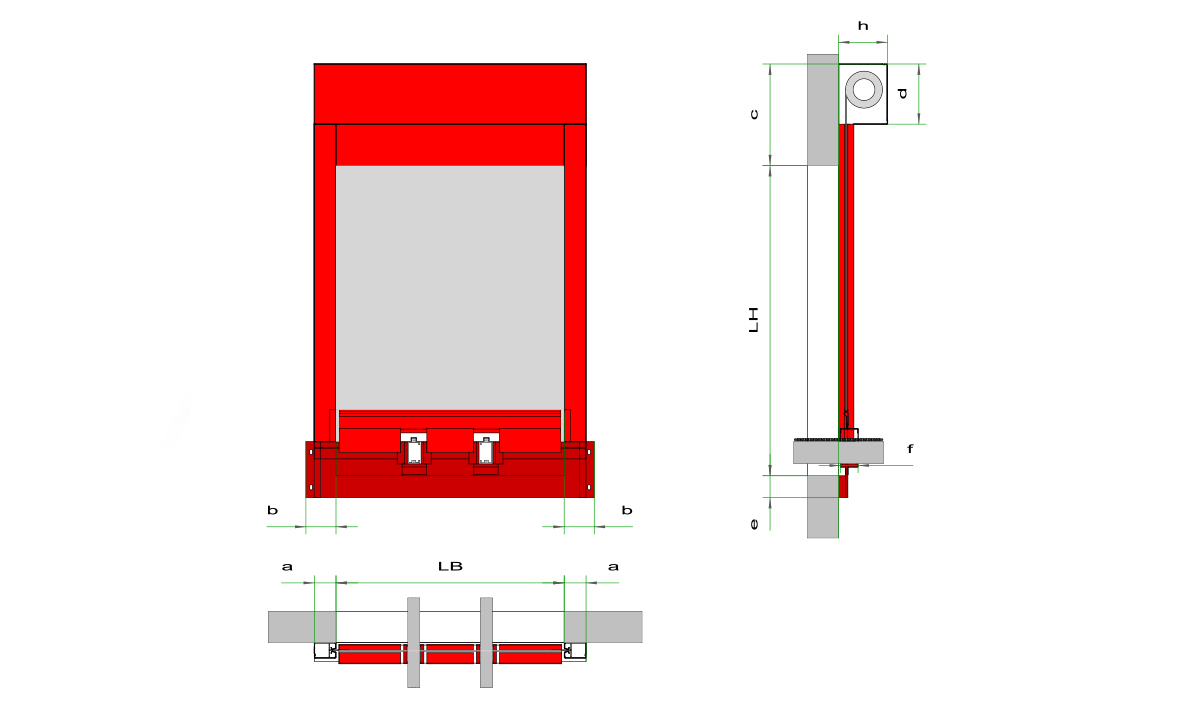

Product description

As a textile roll-up conveyor system closure, ECClos-FLEX is characterized by its small space requirement. The system closes vertically from top to bottom and is also suitable for very large openings. It is designed for discontinuous and separate conveyor systems such as belt, roller and suspension chain conveyors. The closure meets the requirements of fire resistance classes E 90 and EW 60 (tested according to DIN EN 1366-7). The protection goal EI 90 can be achieved by means of a sprinkler system to be provided by the customer.