FIBERSHIELD®-P

Product description

Ideal for efficient fire protection of large dimensions: The textile fire protection curtain Fibershield®-P is approved for widths up to 10 m and drop lengths of up to 7.6 m. Larger dimensions are technically feasible. Different classifications can be achieved flexibly by using different types of fabric. The curtain can be moved with just one drive system. As standard, Fibershield®-P is equipped with the tried and tested "Gravigen" drive, which closes without requiring an external power source. With numerous design variants, Fibershield®-P offers plenty of scope for customer-specific solutions.

| Type | Textile fire protection curtain |

| Achievable protection goals | EI - with fire load free zone | EI - with sprinklers |

| Proof of usability | General technical approval (Z-6.60-2127) |

| Fabric | Heliotex | Protex 1100.1 A2 |

| Fire load free zone | Heliotex: EI 30/60/90min 20/30/50 cm | Protex: EI 30/60/90min 100/150/200 cm |

| Verification | Z-6.60-2127 | UB III/B-07-010-1 | LP-1216.2/02 | UB III/08-033 | UB III/B-04-045 | UB 3.1/ 09-018 | UB 3.3/09-202 | UU IV/00-39-1 | 08/32309876 | 2011-Efectis-R0495 |UL 10 (b) (2009) | UL 10 (c) (2009) | UL 10 (d) (2009) | NFPA 252 (2012) |

| Closing direction | From top to bottom |

| Fire resistance | E 30 | E 60 | E 90 | E 120 | EW 30 | EW 60 | EW 90 | EW 120 | classified according to DIN EN 13501-2 |

| Closing cycles | C2 |

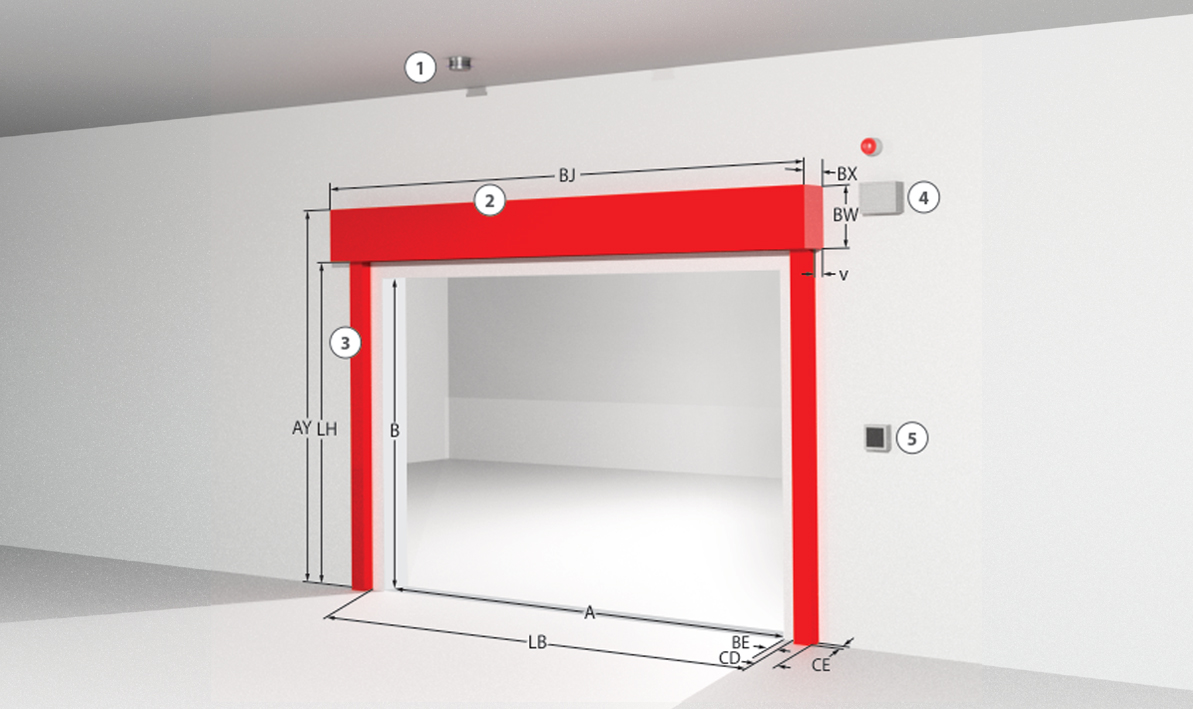

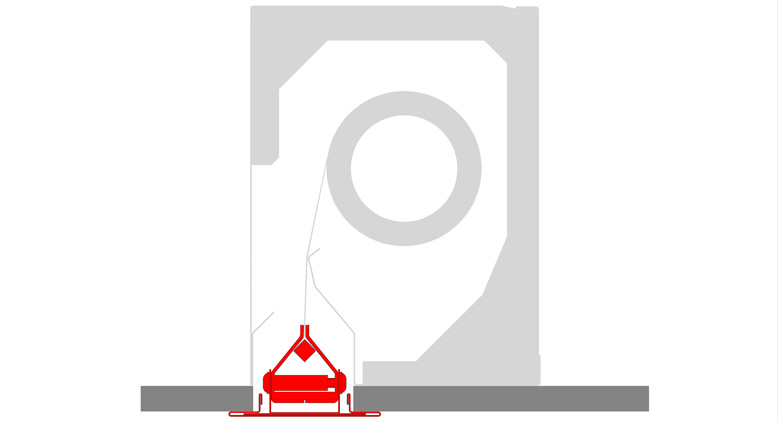

Legend System components:

1 = Smoke detector

2 = Casing

3 = Side guide

4 = Fixing bracket

5 = Fabric

6 = Closing element

7 = Tubular motor

8 = Control module

9 = Control with operating unit

10 = Manual release

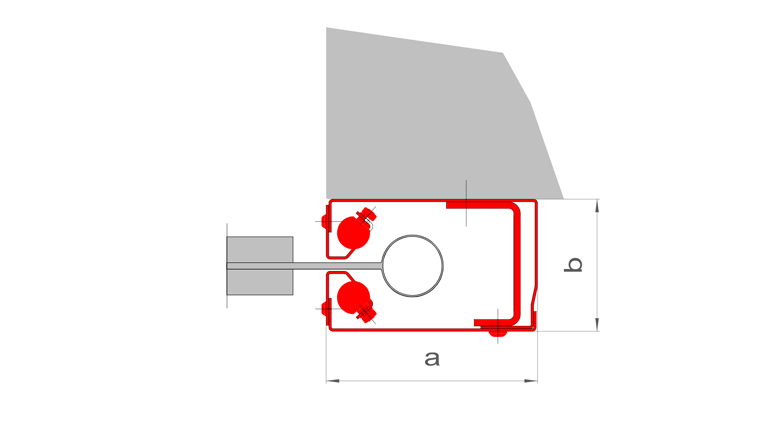

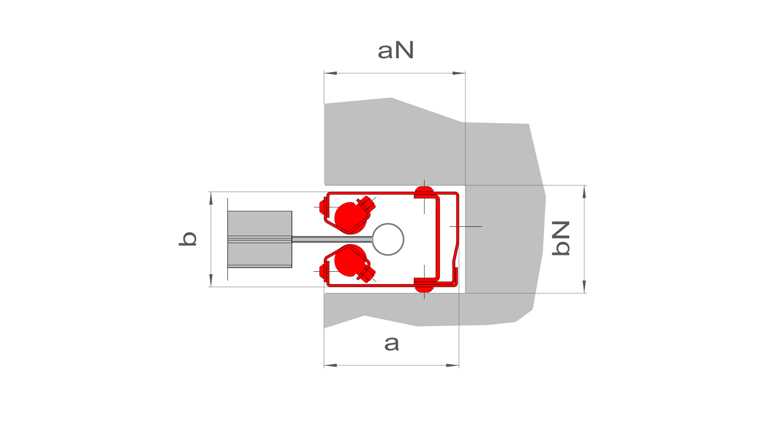

Constructive system design (System drawing)

| Classification | Fabric | System width (SB) | Drop length (AL) | t (mm) | h (mm) |

| EW 90 | Heliotex EW | ≥ 0,8 m - ≤ 10 m | ≤ 2 m | 190 | 250 |

| EW 90 | Heliotex EW | ≥ 0,8 m - ≤ 10 m | ≤ 6 m | 235 | 290 |

| E 90 / EW 30 | Protex 1100.1 A2 | ≥ 0,8 m - ≤ 1,6 m | ≤ 3,5 m | 190 | 250 |

| E 90 / EW 30 | Protex 1100.1 A2 | ≥ 1,6 m - ≤ 10 m | ≤ 3,5 m | 190 | 200 |

| E 90 / EW 30 | Protex 1100.1 A2 | ≥ 0,8 m - ≤ 10 m | ≥ 3,5 m - ≤ 6 m | 190 | 250 |

| E 90 / EW 30 | Protex 1100.1 A2 | ≥ 0,8 m - ≤ 10 m | ≥ 6 m - ≤ 7,6 m | 235 | 290 |

(Special sizes on request - technically feasible up to dimensions 22 x 9m (Protex 1100.1 A2) or 12 x 6 m (Heliotex))

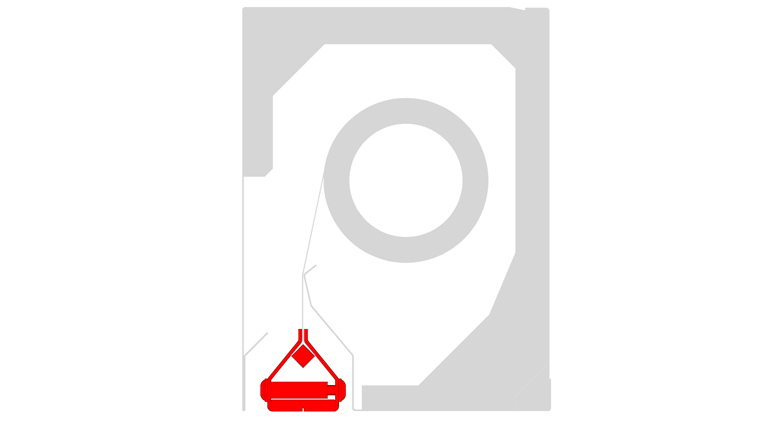

Closing strips

Standard

Typ 4,6

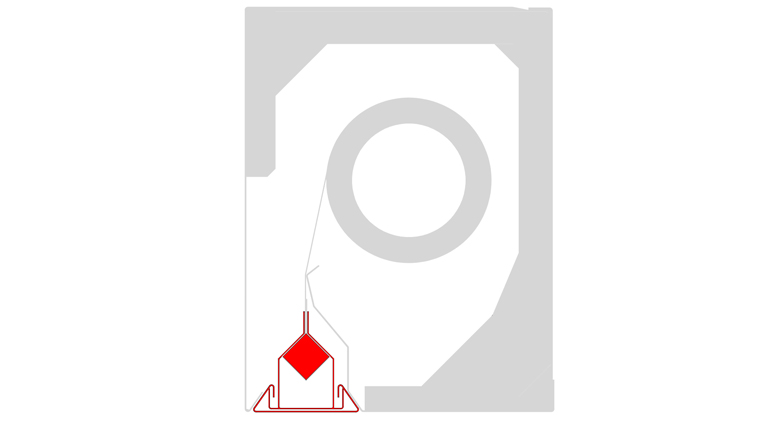

Spring-loaded closing strip

Typ = 3,84 F (Special)

Spring-loaded closing strip

Typ = 4,6 F (Special)

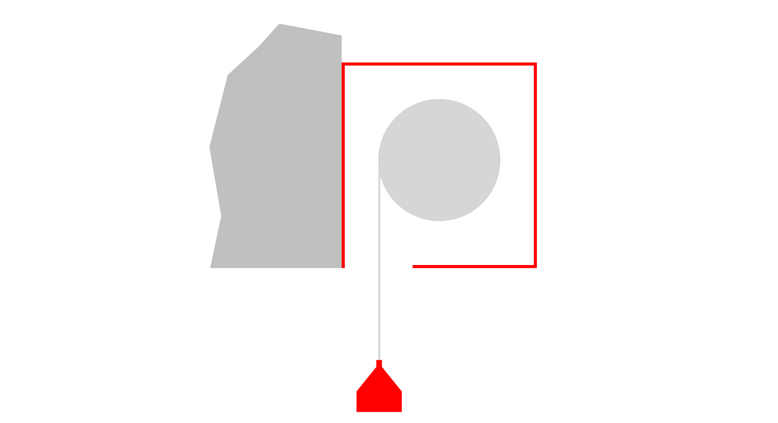

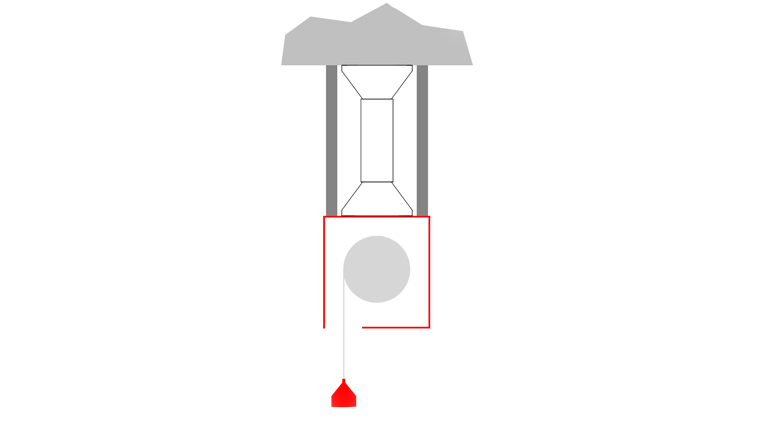

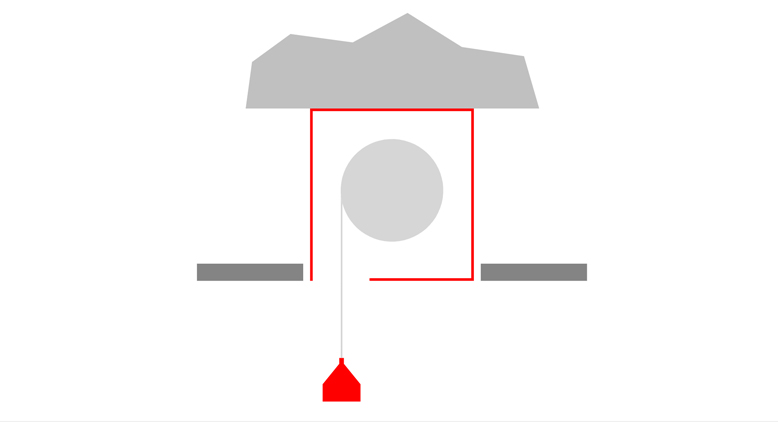

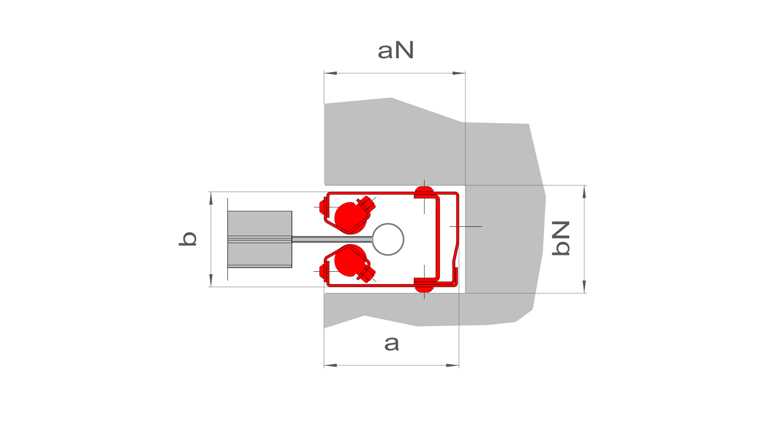

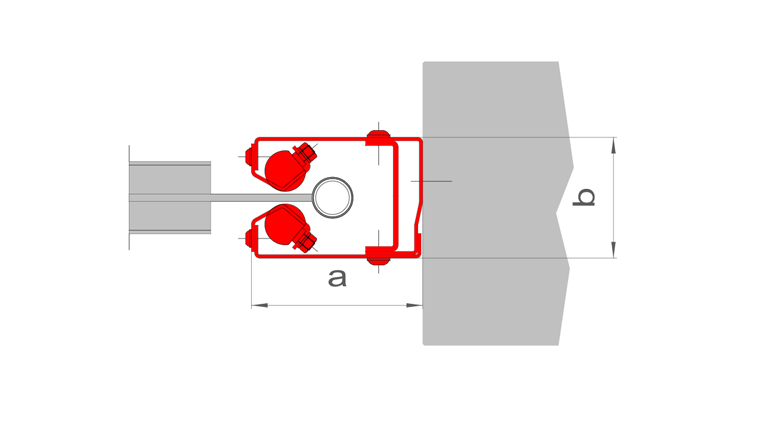

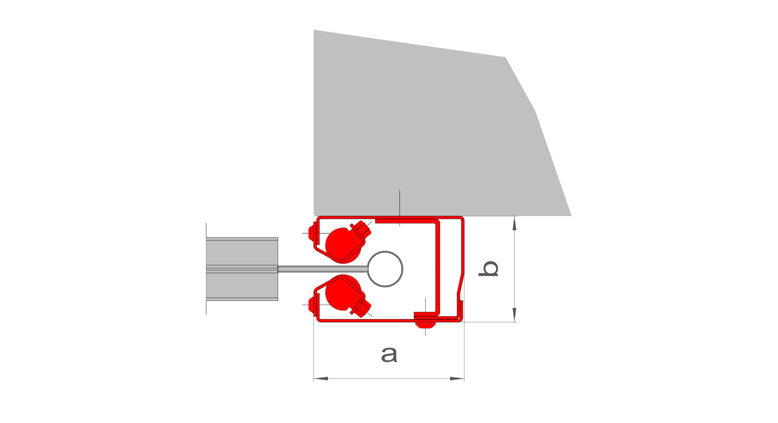

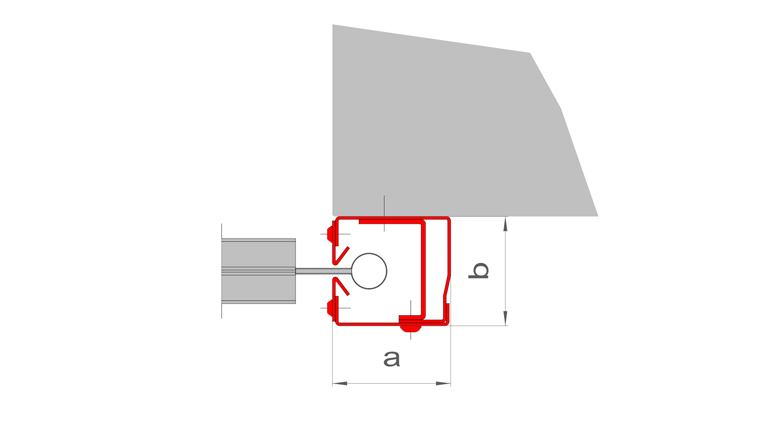

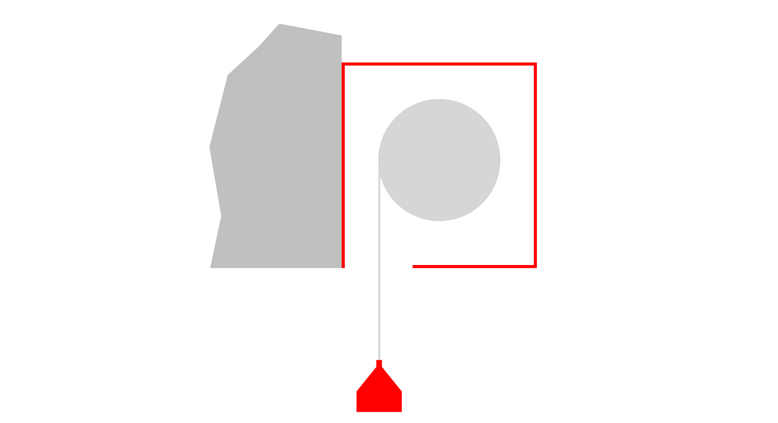

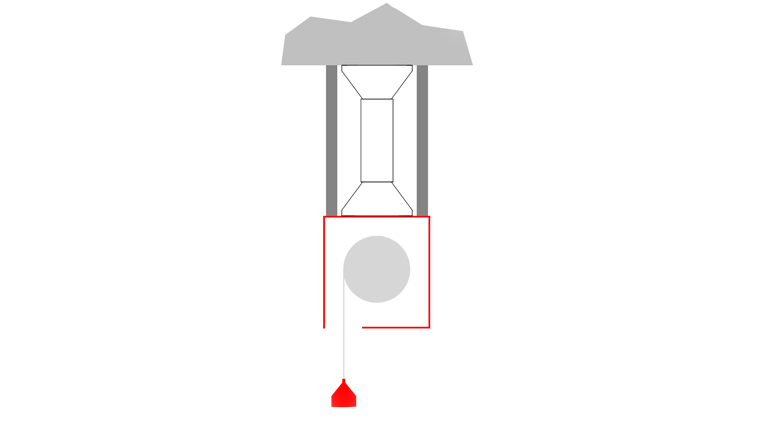

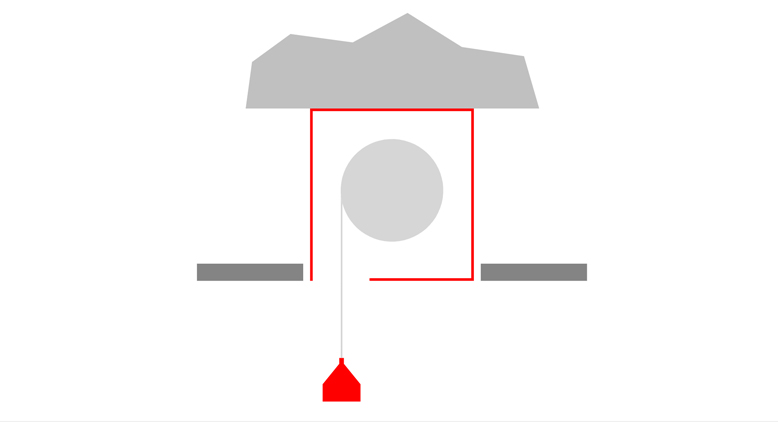

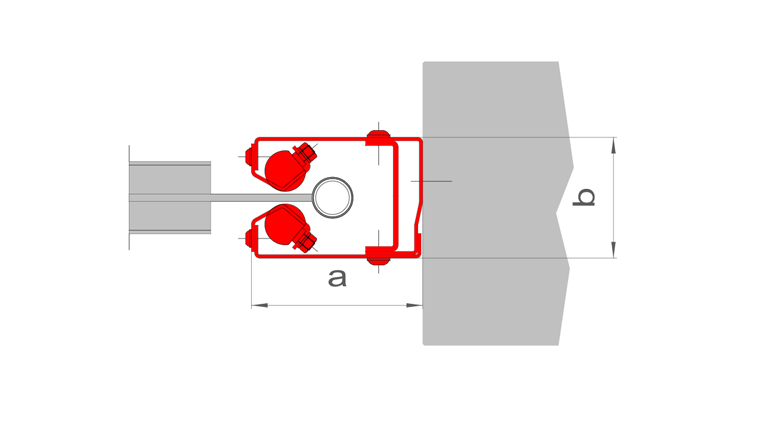

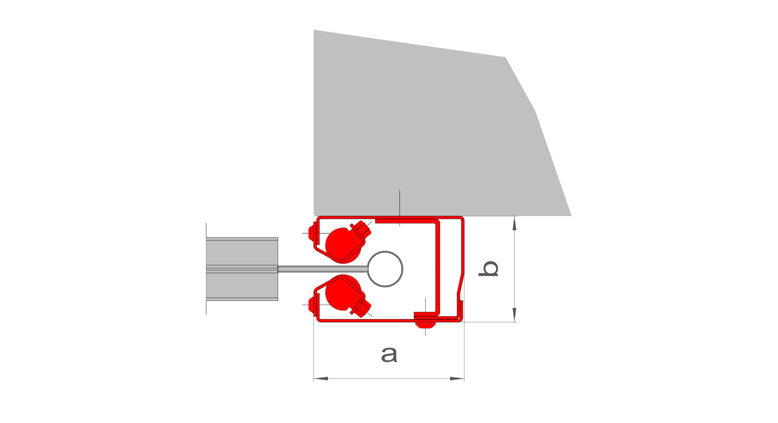

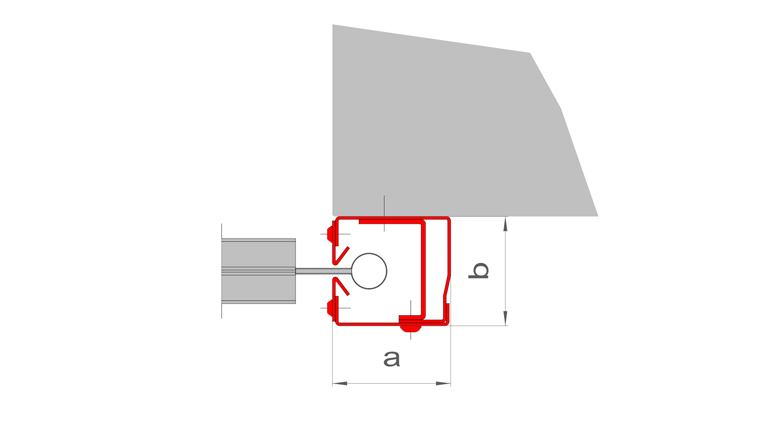

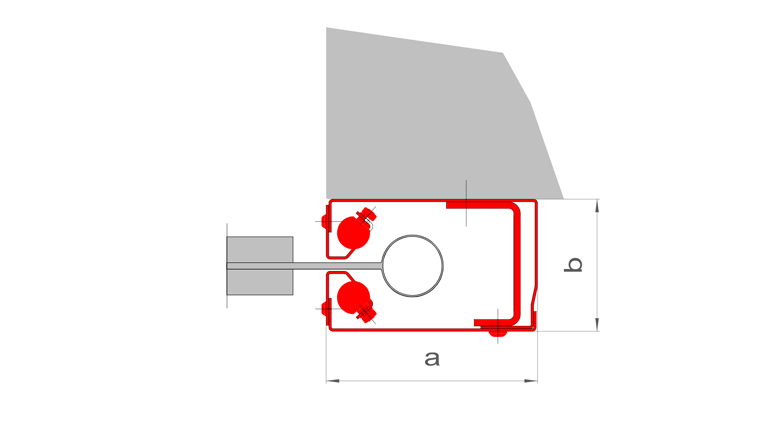

Casing installation options

Wall mounting

Suspension mounting

Ceiling mounting

Guide rails

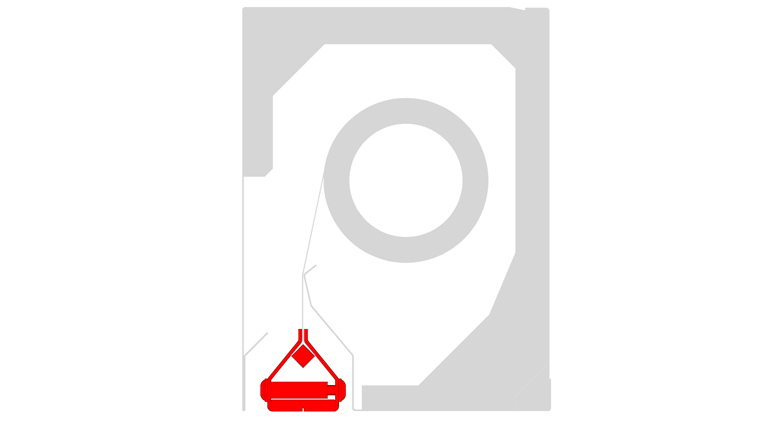

Type 105 E (niche)

a = 105 mm

b = 74 mm

AL = ≤ 6 m

A = ≤ 50 m²

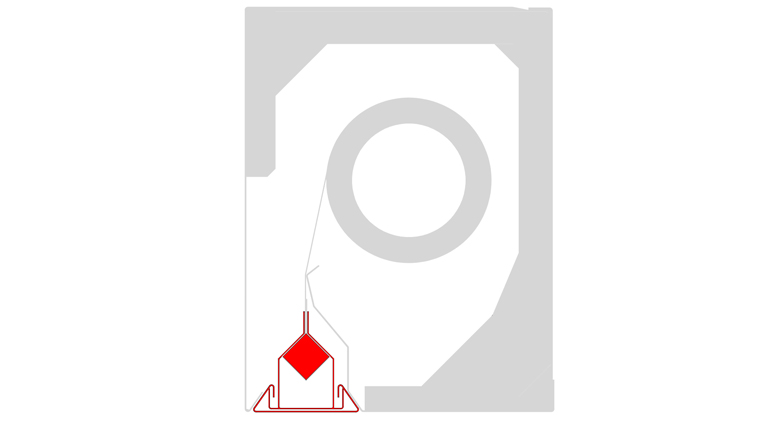

Type 105 E (embrasure)

a = 105 mm

b = 74 mm

AL = ≤ 6 m

A = ≤ 50 m²

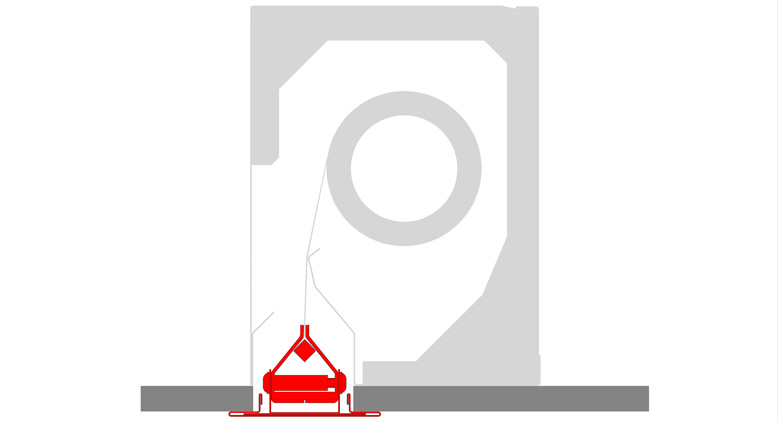

Type 105 E (Wall)

a = 105 mm

b = 74 mm

AL = ≤ 6 m

A = ≤ 50 m²

Type 80 E

a = 80 mm

b = 74 mm

AL = ≤ 3,5 m

A = ≤ 18 m²

Type 160 E

a = 160 mm

b = 100 mm

AL = ≤ 9 m

A = ≤ 120 m²